Precision Machining

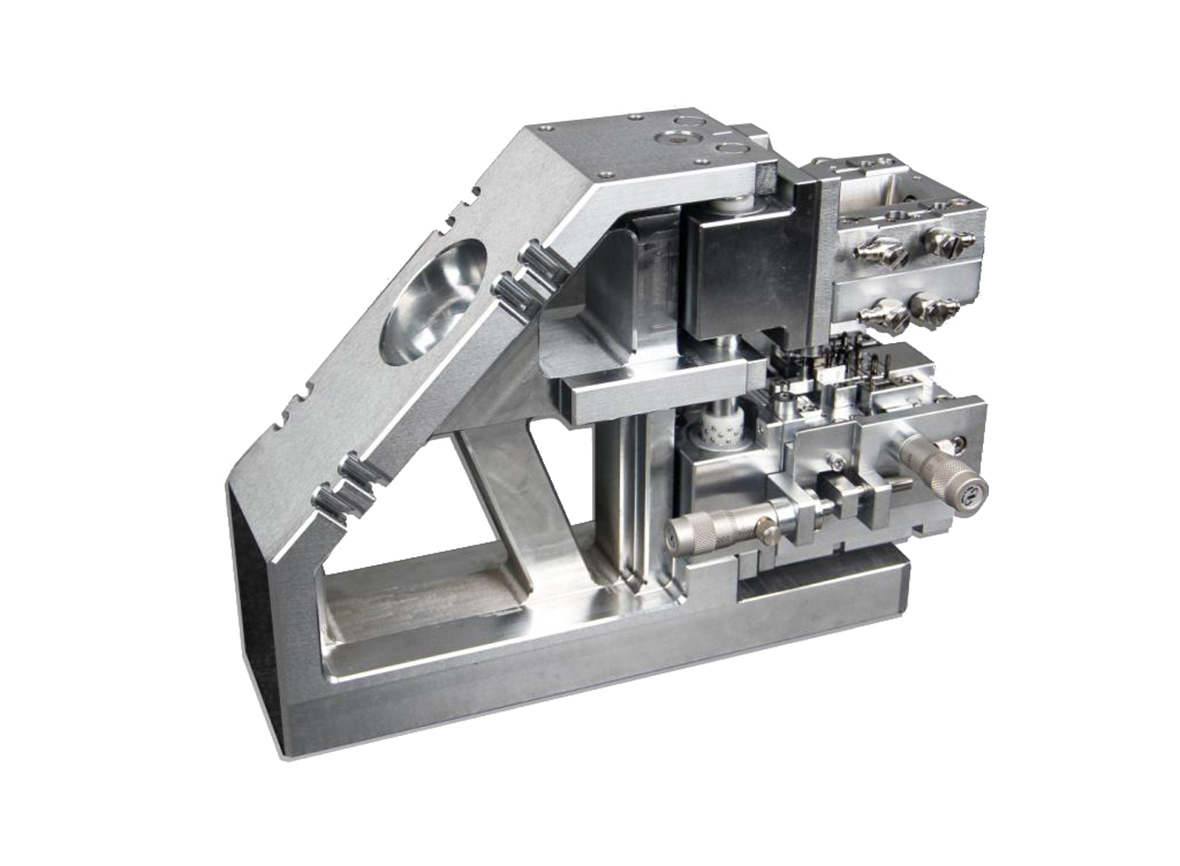

Since its establishment, Chengdu Innorev has successively deployed CNC machining centers (including Roders, Okuma), CNC turning and milling complex centers, honing, slow-speed wire cutting, three-coordinates, projectors, altimeters and electric spark, grinding machines, milling machines and many other advanced processing equipment and testing equipment from Germany, Switzerland, Japan and other countries. Chengdu Innorev not only possesses these abundant equipment resources in the fields of precision parts, precision fixtures/toolings, and precision stamping dies, but also has rich experience and technique in processing and assembly. Precision mechanical equipment such as wire cutting, slow-speed wire cutting, honing, grinding machines can meet the accuracy requirements of +/- 3um dimensionally. The company has gathered a large number of skilled and experienced operators and inspectors, with those employees working over five years accounting for about 60%. The company established a strict quality control system, from the self-inspection in production and IPQC process inspection to the full-scale inspection before the shipment of finished products. The products have passed the ISO9001 and ISO14001 certifications. We provide customers with satisfactory delivery and high quality products by using those equipment with extensive technical knowledge and total quality control system.

High dimensional requirements: key position, parallelism, flatness, verticality, symmetry and contour should be within 0.003 mm

High dimensional requirements: the dimensional tolerance should be 0.002 mm; position, parallelism, flatness, verticality, symmetry and contour should be within 0.002 mm

High dimensional requirements: the dimensional tolerance should be 0.002 mm; position, parallelism, flatness, verticality, symmetry and contour should be within 0.002 mm

High dimensional requirements: the dimensional tolerance should be 0.003 mm; position, parallelism, flatness, verticality, symmetry and contour should be within 0.003 mm;

High dimensional requirements: the dimensional tolerance should be 0.003 mm; position, parallelism, flatness, verticality, symmetry and contour should be within 0.002 mm;

Processing by CNC turning and milling composite center

Processing by CNC turning and milling composite center